The integration of technology into every aspect of life is increasing rapidly for many reasons with smart cities (CTIA and other initiatives) and smart factories (Industry 4.0) providing specific locations where this integration is frequently cited. A less well-known destination for technology is farming. However, smart farms or smart agriculture efforts in Agriculture 5.0 demonstrate that the technological revolution is addressing the need for greater efficiency, sustainability, and resilience against environmental changes in farming as well. In addition to artificial intelligence (AI), smart sensing, automation including robotics, and connectivity through the Internet of Things (IoT), advanced LED horticulture lighting is a critical part of the technologies needed to transform our food supply and provide the complete solution.

The Problem(s) in Farming

Global food production has historically had areas where sufficient food could be grown to satisfy the local population and areas where annual crops were sometimes, or frequently, inadequate to feed everyone. These same situations exist today and without proper attention, they could get much worse due to the different issues modern society is facing. These issues include: (1) a significantly increasing population, (2) reductions in the amount of usable farm land, (3) concerns about shipping food products long distances because of the need to reduce carbon emissions and spoilage, and more.

Unlike previous generations, we have an increasing number of advanced technologies to address the modern food problem that fall under umbrella classifications such as smart farming, smart agriculture and Agriculture 5.0. Agriculture 5.0 includes the use of technologies such as artificial intelligence, smart sensors, robotics, IoT connectivity and more to address the problem.

Controlled-environment agriculture (CEA) is a key part of Agriculture 5.0 to transform agriculture by creating fully controlled environments for growing plants. These controlled environments include hydroponic (grown in water) and aeroponic (grown with air exposed roots) methods inside controlled structures such as greenhouses, vertical farms and growth chambers. An essential aspect of CEA is controlled/targeted lighting. Without requiring sunlight, controlled lighting provides the best possible and even optimum growing conditions for each crop allowing them to grow out-of-season or in a completely different climate than where the controlled structure is located.

Since CEA farms can be established anywhere, they can be located far closer to consumers than most traditional farms. This close proximity means reduced transportation effort/cost and time, so food can arrive fresher and with less food waste in transit. Using CEA farms, one company claims 94% less food waste than traditional farms.

The Horticulture Lighting Solution

With input collected and shared from Agriculture 5.0 technologies, the data is then analyzed and used to optimize various processes such as crop selection, irrigation, and fertilization. Horticulture lighting plays an essential role in these processes. Three key aspects involved in horticulture lighting include: (1) enhanced photosynthesis with optimal spectra, (2) year-round crop production / longer growing seasons, and (3) improved crop quality and yield with the reduced use of pesticides.

For CEA and other lighting applications, light-emitting diodes or LEDs have higher efficiency and greater versatility than previously used metal-halide, fluorescent, high-pressure sodium (HPS) or neon lamps. This means the availability of more usable light energy to the plants for a given power load and less heat generated. In addition, the lighting can be customized and optimized for the specific needs of different types of plants and provide growers with cost reduction options for water, fertilizers and pesticides. Some CEA greenhouses report using 99% less land and 98% less water than conventional growing practices.

Controlled-environment agriculture simplifies keeping contaminants out of crops for a safer food supply. Also, with food grown by CEA in harsh climates or highly unpredictable weather situations, crops are protected from dangerous storms and floods solving another food supply issue in an ever-changing world.

Implementing Advanced Horticulture Lighting

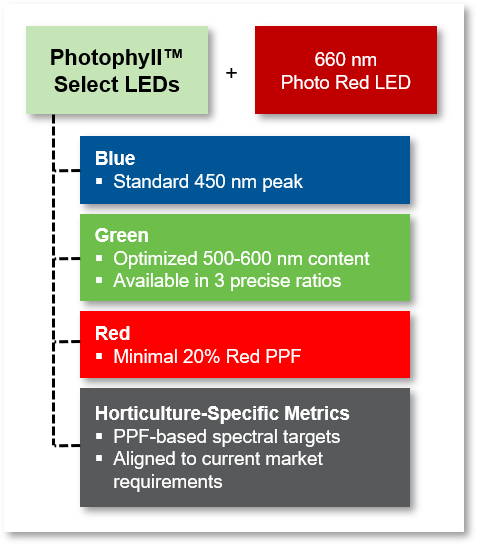

LED lighting technology designed specifically for horticulture applications provides significant improvements over previous approaches. Unlike traditional lighting for human vision, advanced horticulture lighting systems require application-tuned spectral content, high efficacy and long lifespans. To address these requirements and easily integrate with smart farming systems, Cree LED’s Photophyll™ Select LEDs provide a breakthrough approach to fully characterize products with horticulture metrics. These include photosynthetic photon flux (PPF) and red PPF %, instead of traditional lighting metrics, such as correlated color temperature (CCT) and color rendering index (CRI).

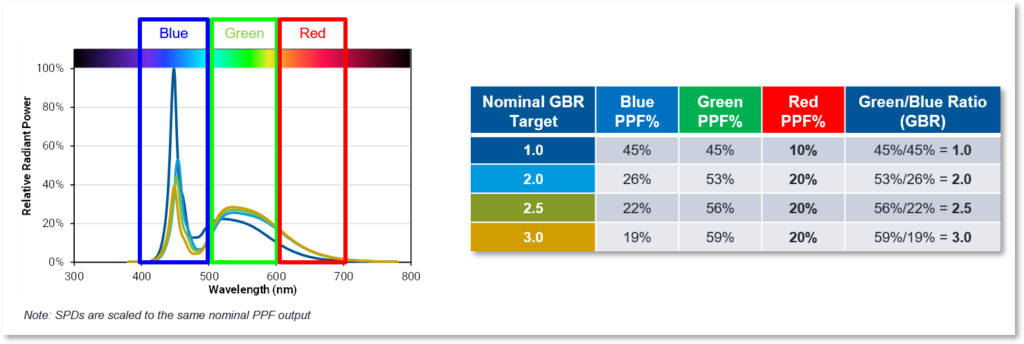

Using a new phosphor-converted LED color with blue and green spectral output tuned for horticulture applications, these LEDS are the first to deliver an advanced spectrum that provides precise control over the green/blue ratio (GBR). Figure 1 and 2 show the changes to green and red wavelengths and GBR targets. Green wavelengths (500-600 nm) are optimized and available in three nominal GBR targets. Red values have been reduced to a typical of 20% Red PPF. Minimized red content in Photophyll Select LEDs allows for maximum contribution from efficient 660 nm Photo Red LEDs and improves system PPF and PPF/W by 6% vs. White + Red designs. This provides advanced spectrum and performance capabilities for horticulture applications. Designed to replace the white LEDs that are common in two-channel White + Red horticulture luminaires, Photophyll Select LEDs can be used with XLamp® XP-L Photo Red S Line LEDs that are optimized for high-performance applications in greenhouses, vertical farms and other large-scale growing operations.

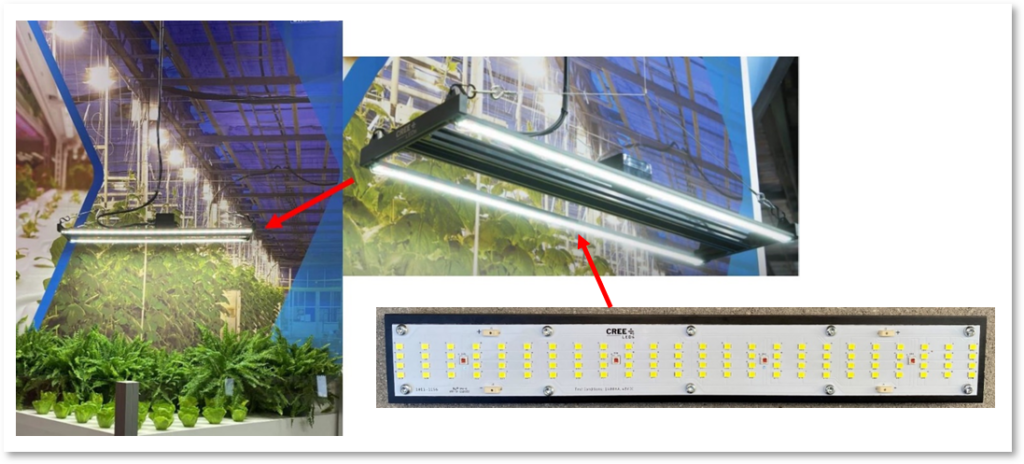

A reference design (shown in Figure 3) utilizing 2 LED Channels that consist of Photophyll Select + 660 nm Photo Red LEDs, demonstrates better performance (up to 6% efficacy improvement) and 33% lower LED count (for reduced system cost). At the same time, this design maintains the same GBR and red % at the same input power. The higher performance of Photophyll Select LEDs means that luminaire designers can either:

- Improve performance (output and efficiency) at the same LED cost or

- Reduce cost (by using fewer LEDs) and maintaining the same performance (output and efficiency)

Designers of horticulture applications can anticipate continued improvement of the overall PPE of horticulture LEDs. Specifically, today’s horticulture LEDs are in the 50-80% efficiency range, so improvements can be made to further increase efficiency.

Customized LED lens shapes are another area where changes can occur to address target and customer-specific applications with different light emission patterns.If shaping the light output can be performed at the LED component level, the overall luminaire efficiency can be increased and the luminaire cost reduced.

For horticulture luminaire system designers, the bottom line from using Photophyll Select LEDs means improved energy efficiency, customizable spectrums, reduced cost and lower heat output – essentially, substantial crop growing improvements in Agriculture 5.0.

Lighting: The Way Forward to Smarter Agriculture

Cree LED partners with leading horticulture luminaire companies to deliver industry best products. RED Horticulture headquartered in Lyon, France is one example.

RED Horticulture envisions a world where sustainable and efficient high-tech greenhouses flourish as the standard production environment for healthy food. A protected setting in which RED’s innovative lighting technologies ensures the continuous production of high-quality nutritious food for the growing global population.

Combining high-tech innovation with advanced hardware, proprietary software and agronomic expertise, RED enables growers to improve crop performance and energy efficiency using their innovative and smart lighting solutions. TeamRED strives to collaborate with growers, experts, expert companies and various leading research organizations to always provide its customers with the best solution. Together, they are committed to sustainable greenhouse farming.

With the increasing problem of feeding a world population projected to exceed 10 billion people by 2050, all of the available, as well as some new technologies will have to be implemented. Advanced LED horticultural lighting has already demonstrated the impact it can have on increasing yield and efficiency as well as the potential to minimize waste and reduce nutrients and hazardous pesticides in crop production. Looking into the future, we can expect next-generation AI systems to monitor plants and adjust the lighting accordingly, with increased scalability and affordability as advanced LED technology becomes even more cost-effective. This approach will provide even greater progress in reducing the environmental impact of farming and provide greater sustainability in the global food supply.